Detail

Water&oil proof and antifouling testing standards

- Categories:Industry news

- Author:

- Origin:

- Time of issue:2021-06-28

- Views:120

Water&oil proof and antifouling testing standards

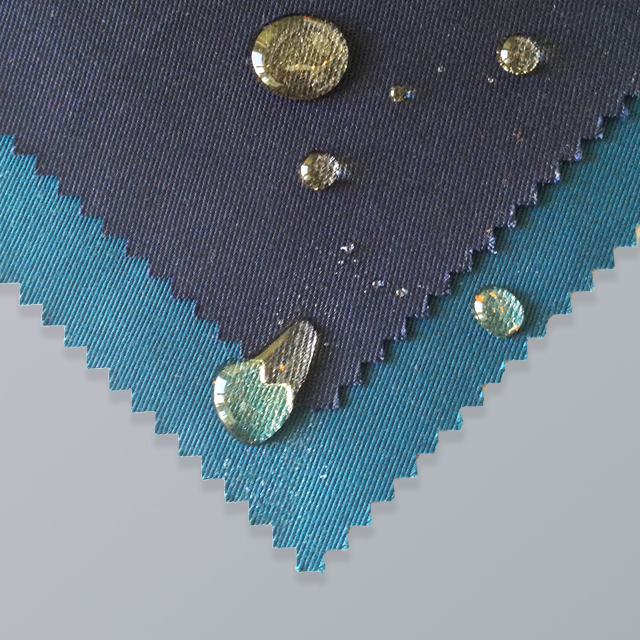

The test mainly assesses the ability of textiles to resist water drenching, stain resistance or oil droplets and dirt under certain conditions. The common oil repellency test is also a kind of dirt repellency test.

Water resistance

Refer to AATCC 22 "Testing and Evaluation of Textile Waterproof Performance-Dip Method" to determine the dynamic water resistance of fabrics. The GB/T 4745 and ISO 4920 standard methods are basically the same as AATCC 22. The fabric sample after water and oil repellent treatment is fixed on a metal ring with a diameter of about 150 mm and placed on a fixed angle of 45°. Shelf. Quickly pour 250 mL of water from the glass funnel above the sample to ensure that the natural spraying is completed within 25-30 s. Remove the fixing ring, tap the fabric face down horizontally, observe the wetting condition of the sample surface, and evaluate its waterproof value.

Oil resistance

According to AATCC 118, GB/T 19977 and ISO 14419 are basically consistent with them, "Oil Discharge: Hydrocarbon Resistance Test" to determine the oil resistance of fabrics. Eight kinds of homologous solvents with gradually decreasing surface tension were used as standard liquids, and different grades of test liquids were dropped on the surface of the finished fabric, and the surface wetting condition of the fabric after 30 seconds was observed. If the final test liquid does not wet the fabric, this level is the oil resistance level of the tested fabric. Level 1 is the worst and level 8 is the best.

Antifouling

The standard of textile antifouling is usually referred to. The test method standard for stain resistance is GB/T 30159.1-2013 "Testing and Evaluation of Textile Antifouling Performance Part 1: Stain Resistance", which is divided into liquid staining method and Solid contamination method. The basic principle of the liquid contamination method is to add a prescribed liquid to the surface of a horizontally placed sample, observe the wetting, wicking and contact angle of the droplets on the sample surface, and evaluate the degree of resistance of the sample to liquid contamination.

Recommended products

FRIENDLY LINKS

Copyright © Xinxiang Zhuocheng Special Textile Co., Ltd. Powered by www.300.cn

The website already supports IPV6

Tel:+86-373-5898962 E-mail:info@zcsafety.com

+86-15560262634

+86-15560262634 Email

Email Message

Message